Drilling Pipe Maintenance Cleaning

CLEANING & LUBRICATION OF DRILLING PIPE

Perform cleaning and lubrication of drilling and production pipes on site or in pipeline and inspection workshops reducing costs by up to 60%, providing operation with patented tools and portable equipment.

Scope of Service:

- Free Technology demonstration.

- Cleaning and lubrication of the tubes on site .

- Reduction of logistics and transport costs.

- Less expensive than any other technology.

- 12m Pipes cleaned in 3 minutes.

- Offshore and onshore cleaning.

- Guaranteed satisfaction.

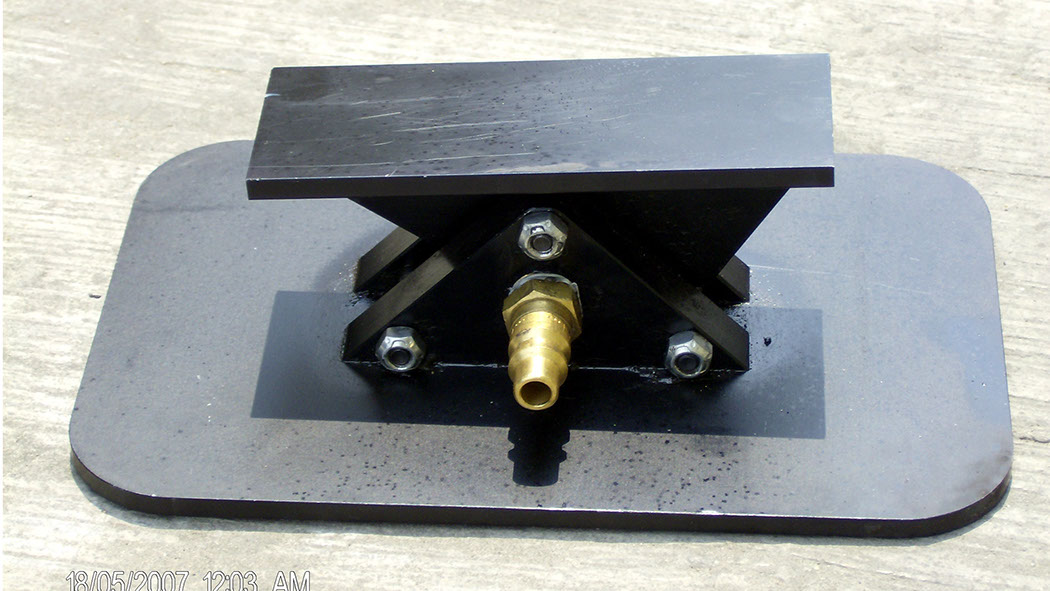

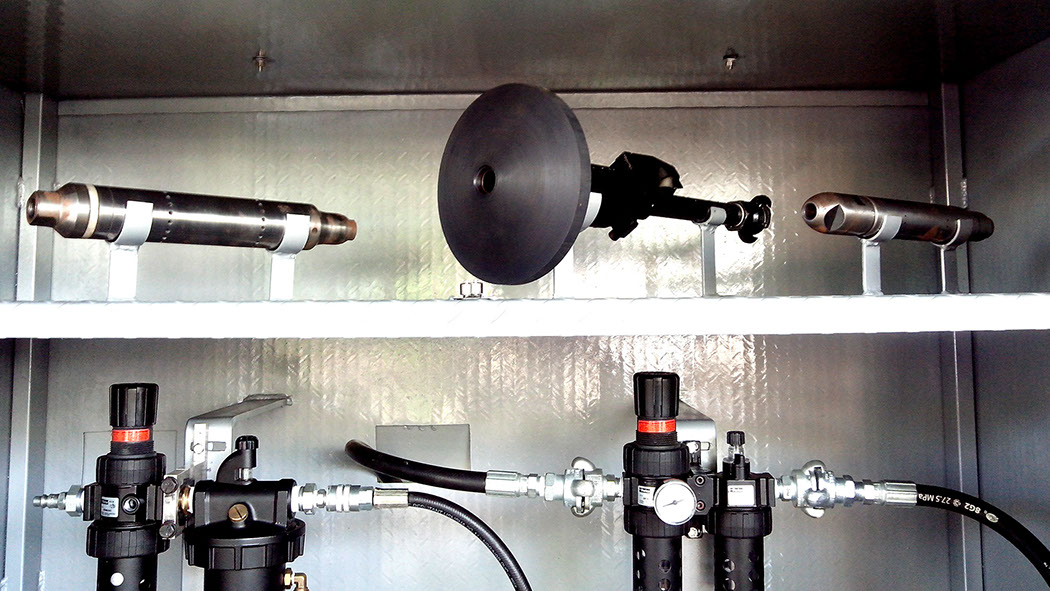

SELF PROPELLED PNEUMATIC TOOL (STX)

PERCUSSION LANCE (PL)

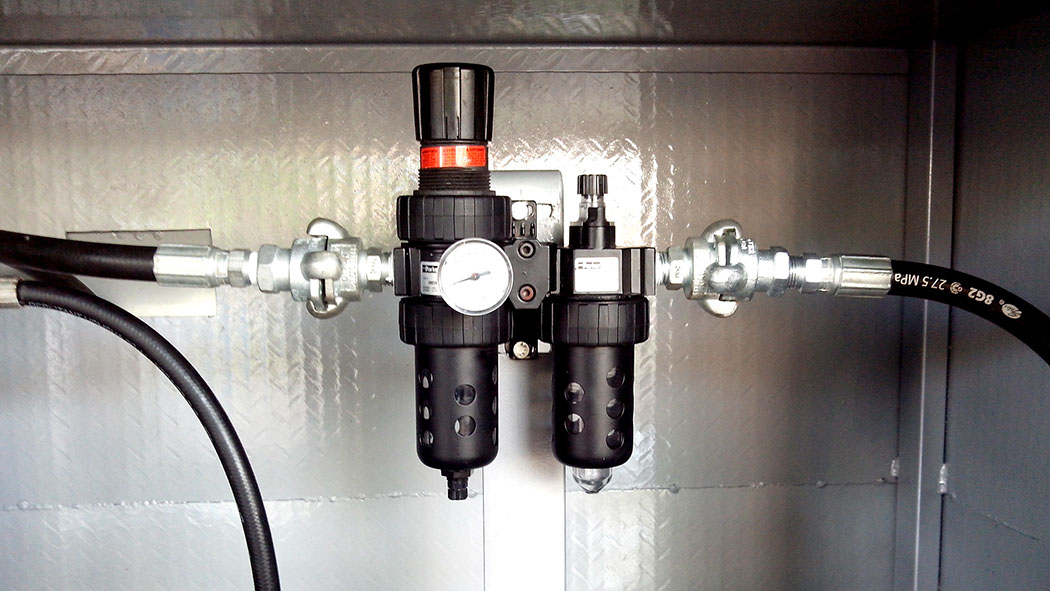

- Min air pressure: 60 PSI

- Max air pressure: 150 PSI

- Air volume: 25 - 85 cfm

- Recommended pressure: 85 PSI

- Air: Lubricated, Filtered, Regulated

- Percussion: 1900 / min

- Min air pressure: 80 PSI

- Max air pressure: 150 PSI

- Air volume: 85 - 100 cfm

- Air: Lubricated, Filtered, Regulated

- Conversion: 80 to 1600 PSI

- Percussion: 4500 / min

DELIVERABLES

- Free Technology demonstration.

- Costs reduction.

- Field cleaning and drilling equipment.

- Speed and Efficiency.

Drilling Common Problems:

- Casing & Tubing Calibration Problems, Drill Collars.

- Pump Pressure Increasing.

- Decreasing of ID by cement deposits.

- Equipment lost time by drilling, drilling & packing blocked.

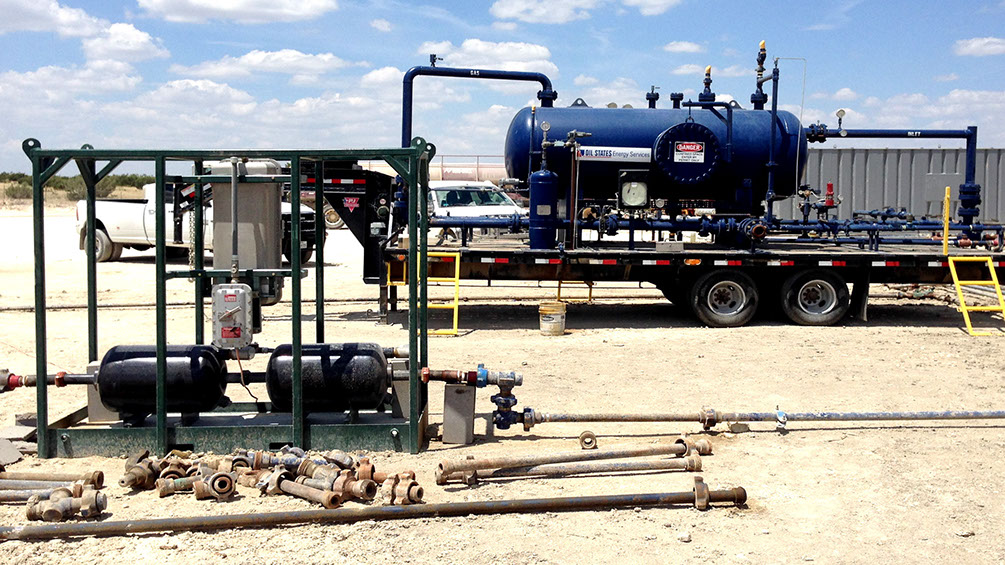

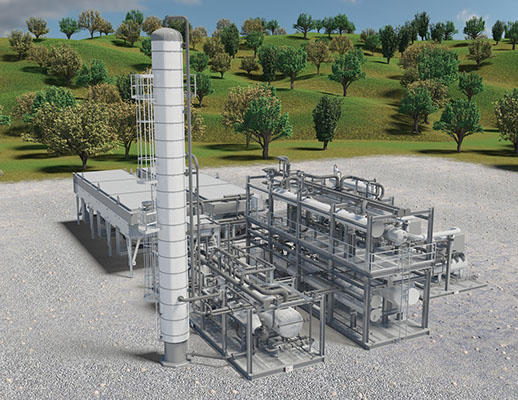

Three Phase Separators, Heaters & Refinement

CONSTRUCTION, REFINEMENT & EQUIPMENT SPECIALISTS

-

Modular Refinery Package EPC

- Process tower, distillation tower.

-

Engineering & Design

- Plant design, separation equipment design, tower design, horizontal tank design, exchangers design.

-

Construction & Procurement

- Material coordination. Schedule & calculating. Procurement, Storage & Logistics. Preparation & Process. Construction. Technical support.

-

Project Management & Planning

- Design, Execution, Evaluation.

-

Technical Support in Site

- Direct supervision, manuals & safety.

-

Civil & Structural Engineering

- Planning, Personnel, Support.

REFINERY CONSTRUCTION

OIL PROCESS TOPPING UNITS

- PEK Structural towers

- Cooling towers

- Reactor towers

- Refined products separation towers

- Process towers

- Heat exchangers

- Heat process exchangers

- Indirect heat exchangers

- Oil distillation units

- Oil toping plant

- Process horizontal units

- Two & three phase separators

- Stainless steel

- Storage tanks

- Filtering units

- Heat exchangers

- Coolers

- Desalter

- Horizontal & vertical heaters

- Atmospheric distillation towers

- Steam generator

- Aeration equipments

- Feeding products pumps

GLOBAL CLIENTS

- ENERFLEX

- EXTERRAN

- HYDRAFAB

- CLEANHARBOR

- PIONEER AIR

- SYSTEMS AID

- LINDSAYCA USA

- INDUSTRIES V GAS

- OPERO ENERGY

- WAYMON GORDAN

- SNC-LAVLIN

- TITAN PRODUCTION

- KW INTERNATIONAL

- RJ ENGINEERING

- AUDOBON

- CROSSTRAILS

- ENERGROUP

- RELEVANT POWER

- SOLUTION AERON

Congenital Water Separators for Oil & Solids

ADVANTAGES

Patented water, oil and solids SEPARATION on site technology in a simple and improved way with the capacity to separate volumes of up to 90,000 BPD of congenital water, reducing operating costs and with the advantage of recovering hydrocarbons in Low and High-pressure systems.

Scope of service:

- Separation of solids and hydrocarbons.

- 100% congenital water cleansing.

- Hydrocarbon recovery.

- Operation in storage tanks.

- Well site operations.

- High and Low Pressure.

- Fully automated.

LOW PRESSURE SEPARATION

HIGH PRESSURE SEPARATION

- Flow handling from 500 to 90,000 BPD.

- Max pressure: 85 PSI.

- Works with separator / chemical / filters.

- 100% oil and water separation.

- Any type oil or water.

- Delivers 100% separated oil and water.

- Can be used in storage tanks.

- Low pressure download.

- Minimal maintenance.

- Oil and water separation.

- Solids separation.

- Max volume 20,000 BPD.

- Water ready for injection in well.

- Working pressure up to 5000 PSI.

- Full portable.

- Zero maintenance.

- Just one operator required

- Any kind of separator attachable.

- Works with artificial lift systems.

DOWNLOADS

Congenital Water Separators

[Español]

2.12 MB

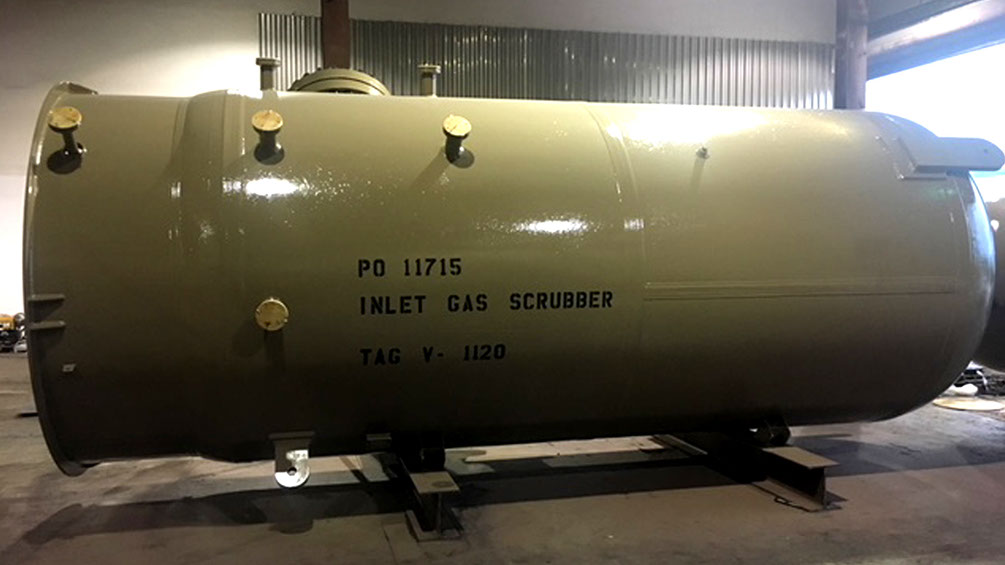

Gas Compression & Treatment Plant

CUSTOM DESIGN & MANUFACTURING

- Design and manufacturing of gas compression and processing plants with capacities from 10 to 150 MMSCFD.

Scope of service:

- We have 4 new plants of 50 MMSCFD.

- We have a 90 MMSCFD plant in stock.

- Custom made design and manufacture.

- Manufacturing and design facility in Houston, TX.

- On-site technical assistance.

- Project analysis.

- Commissioning, operation and start-up of plants.

Deliverables:

- Proven plants with state-of-the-art technology.

- Manufacturing in Houston, TX.

- Short delivery times.

- Field proven technology worldwide.

- Turnkey project analysis.

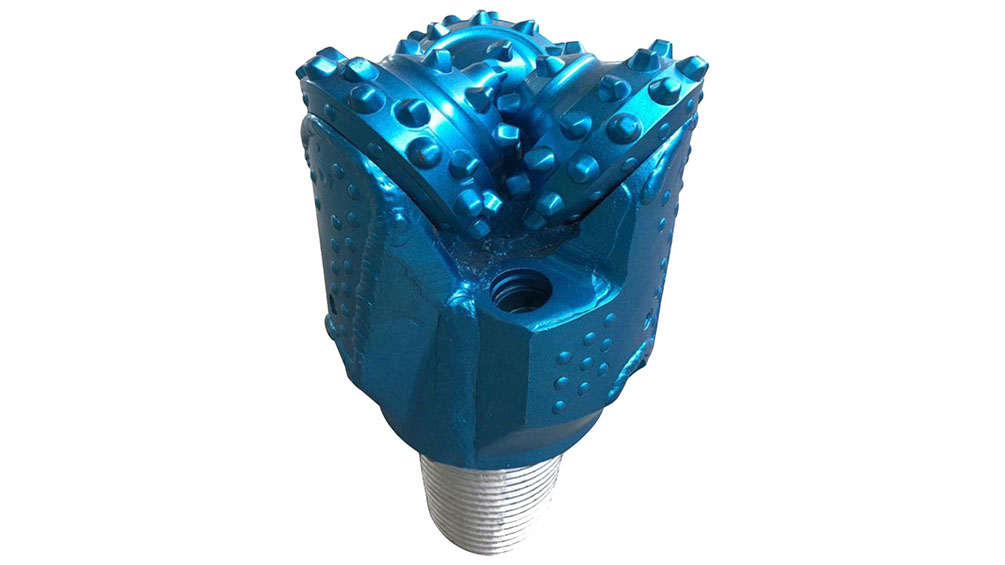

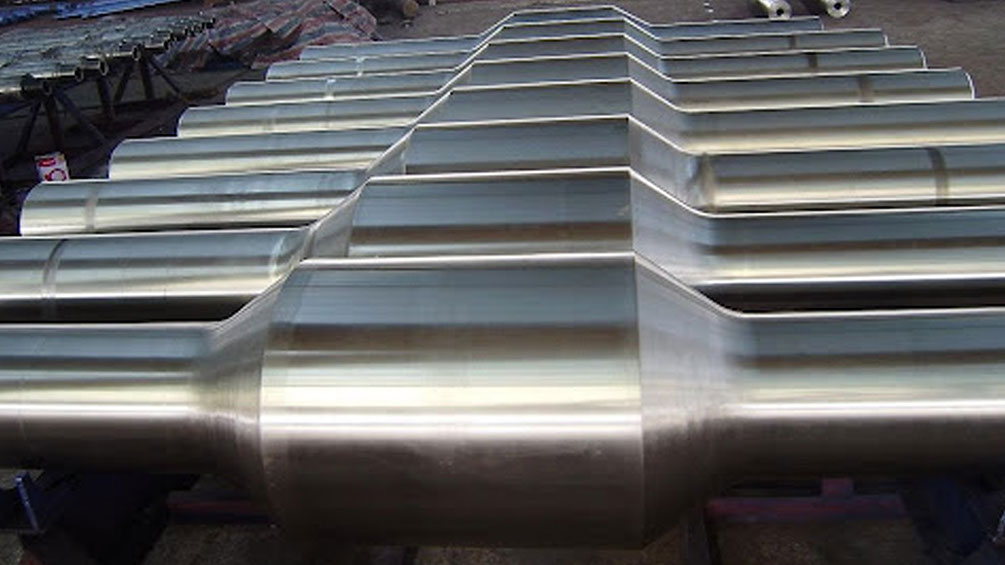

Rental of Drilling Pipe & Inspection Service for Tools

WELL DRILLING & TERMINATION (MEXICO ONLY)

- Rent and sale of well drilling pipe services as well as tools for drilling, stabilizers, davits, including field supervision, inspection and maintenance.

Scope of Service:

- Complete Drill Pipe strings.

- Drilling and production pipe inspection service.

- Drilling tool rental.

- Base of operations in Villahermosa, Mexico.

- Base of operations in Tampico, Mexico.

- Offshore service.

- Integrated pipe and tool services.

Deliverables:

- Drill string design.

- Integrated services.

- Drilling tools.

- Tool inspection and maintenance.

Portable Drilling Sludge Treatment

PRFS (PORTABLE RESTORE FLUIDS IN SITE)

Main Solid Troubles:

- Increase drilling time without production (NPT).

- Reduced penetration rate (ROP).

- More risk of differential adherence.

- Increase resistance and friction.

- Increase of erosion of surface equipment.

- More risk of circulation loss and well damages.

- Deficient cementation.

- Increase environmental impact.

- Increase well drilling time.

- Increase costs.

ADVANTAGES

Treatment of drilling MUDS on site reducing the logistics and drilling times of the equipment.

Scope of service:

- Centrifugal removal of undesirable solids in the mud.

- Integrated MUD recycling tanks included for mixing.

- Fully portable on-site operation.

- Improved logistics.

- Reduction of operating costs.

- Prioritize drilling operations.

- Perform an analysis of the wells with the greatest potential.

- Reduce well intervention costs without equipment.

Deliverables:

- Three units available to work.

- Costs reduction.

- Drilling time reduction.

- Logistics cost reduction.

- Increased MUD life.

TECHNOLOGY

The importance of Technology:

- High and low gravity solids removal.

- Precise adjustment of spin container for an optimal cut.

- High RPMS for more G Force.

- Variable speeds to assure baryta recovery.

- Low RPMS for solids with more specific gravity.

- The operator adjusts according to the process.

Spin Function:

- Dangerous solids removal for sludge from 5 to 10 microns size.

- To produce dry cut.

- Baryta recovery.

- Dehydration, solids and fluids separation with polymer improvement.

In site recovery. Solids control method:

- Dilution: New fluids addition.

- Displacement: Partial liquid replacement.

- Mechanical separation: Drilling solids removal (By different size and density of particles).

- Works on 440 V.

- Can take power on site.

- Works with power generator.

- Low noise operation.

- Can be handle by two person.

- Minimal maintenance.

- Controlled programming.

- Avoids fluid transport.

- Dam connection.

- Tank connection.

- Tanker truck connection.

- Full portable.

- Minimal staff.

- Can works 24/7.

- Solid waste chute.

- Solid removal software.

- Membrane to avoid leaks.

- Ecological membrane.

Bombeo e Inyección de Agua Congénita

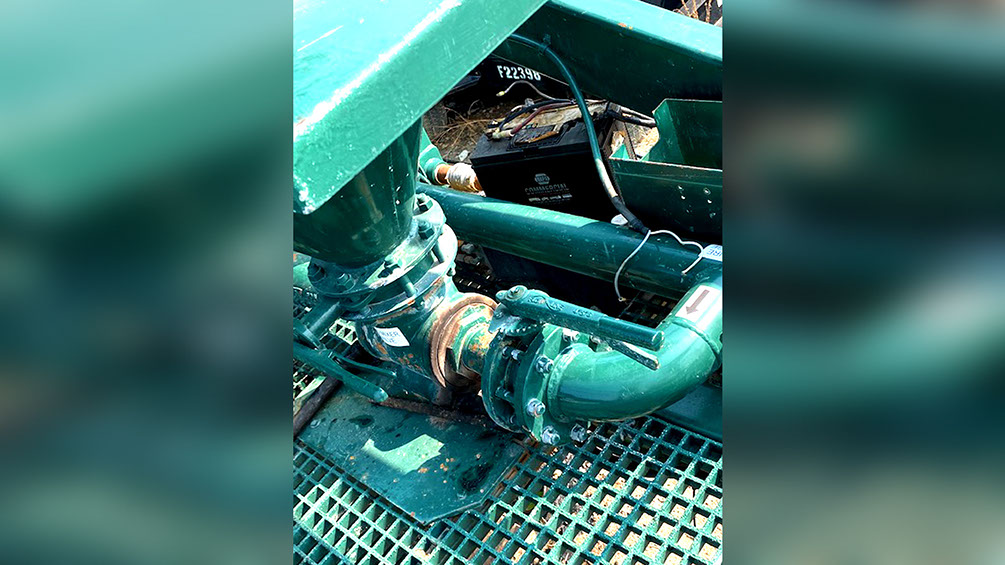

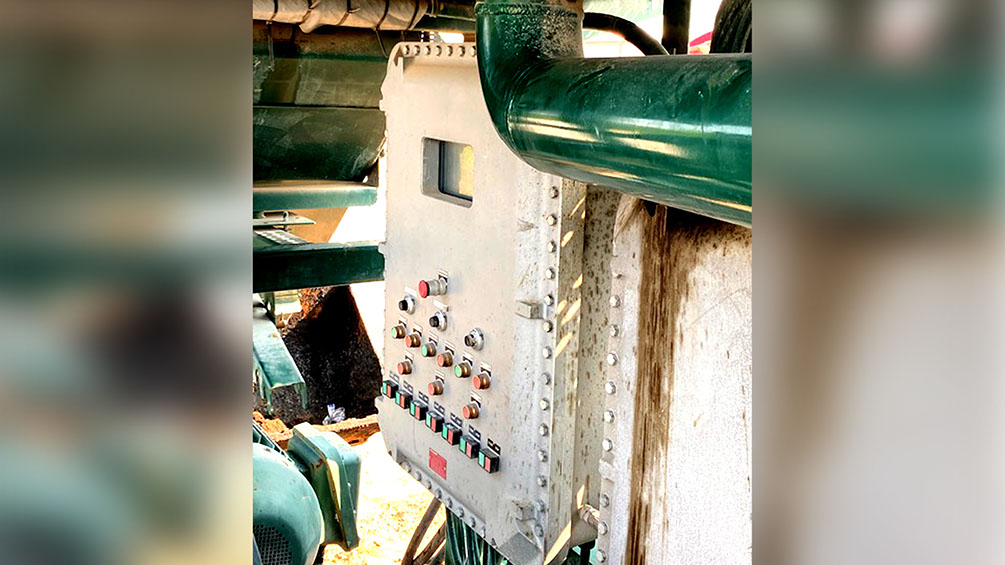

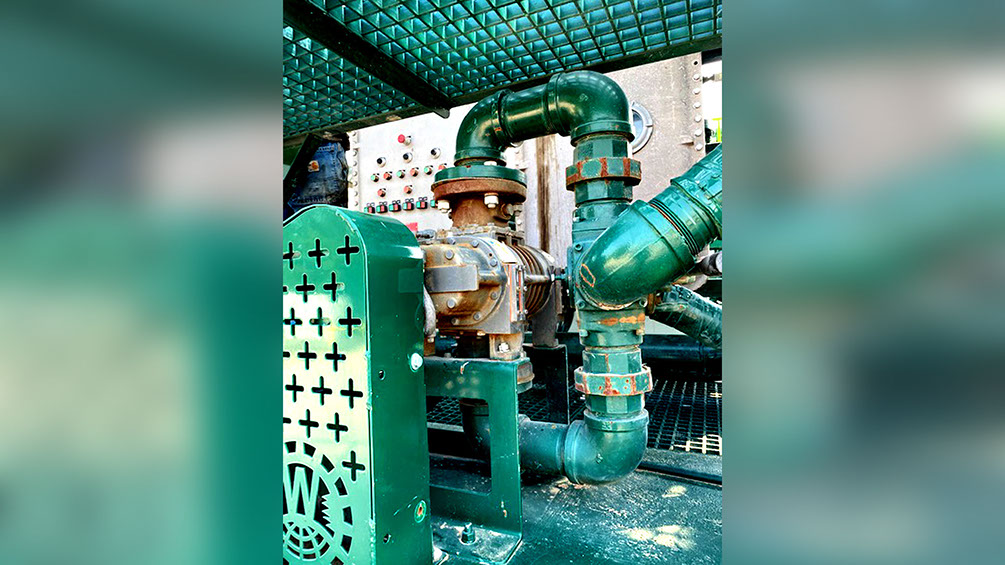

MIPS (Multiphase Intelligent Pumping System)

Automated equipment for the intelligent injection of congenital water with a data collection and management telemetry system.

The MIPS® (Multiphase Intelligent Pumping System) is designed for fluids handling, transport and injection to different operational solutions, using artificial intelligence techniques as Machine Learning and multi variable

control.

MIPS® DESCRIPTION

Pumping System - CMPP® / HCPS®

It's made-up of rotor stator with elastomeric material or spin multi phase pumps and system control mechanism, to cover any flow required.

Intelligent Controller - CILA2S®

CILA2S® 5G MIPS® with added value embedded applications (AVAS®) to control and monitor the pumping, transport and injection fluids system.

Value Added Applications - AVAS®

The value added applications (AVAS®) are developed using artificial intelligence techniques, which taking and processing data, acquire needed knowledge to control process optimal and efficiently, through suite EKIS® (Embedded Knowledge for Injection Systems).

Cloud Cost Effectiveness Analysis – MIPS® Cloud

MIPS® Cloud - Real time monitor, data storage and cloud cost effectiveness system, about MIPS® conditions, applying the model SOFIA® - Digital Oil Field In Action.

SCOPE OF SERVICE

DELIVERABLES

- Production Increase from 15 to 30%.

- Increase in equipment life up to 50%.

- Cost reduction of up to 35%.

- Central monitoring of field water injection.

- Leak location and cost reduction.

- Management of the hydraulic thrust of the reservoir.

- Increase in daily production of gas and oil.

- Engineering design to improve well productivity.

- Production measurement before and after the intervention.

- Evaluation of results and standardization.

- Economic analysis by intervention calculation ROI.